.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

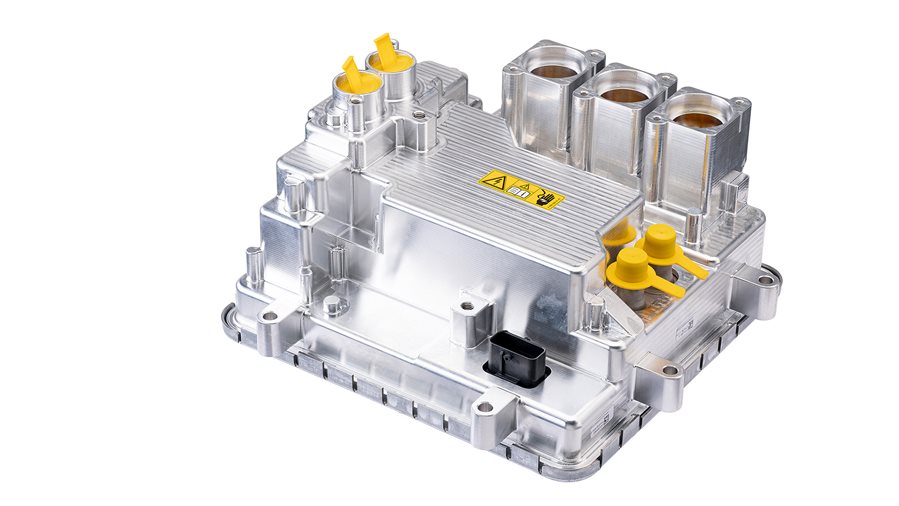

Regensburg, Chemnitz, 17 July 2019. Technology company Continental AG is expanding its fuel cell technology sector. In strategic cooperation with the Chemnitz University of Technology Professorship of Advanced Powertrains (ALF), the newly established Fuel Cell Laboratory for Fuel Cell Technology was dedicated on 17 July. Taking part in the dedication were Martin Dulig, Saxon State Minister for Economy Affairs, Labor and Transport (SMWA) and Deputy Premier of the Free State of Saxony, Stephan Rebhan, Head of Powertrain Technology and Innovation at Continental AG, Prof. Dr. Gerd Strohmeier, President of Chemnitz University of Technology, Prof. Dr. Thomas Unwerth, Chair of the Professorship ALF at Chemnitz University of Technology, and Miko Runkel, Mayor of the City of Chemnitz. With the installation of a large hydrogen tank (H2 Tank) in February 2019 at a laboratory belonging to the Professorship ALF, a central requirement for the expansion to more extensive measuring capabilities was put into place. The Professorship ALF, headed by Prof. Dr. Thomas von Unwerth, has an excellent reputation in the field of research and development of fuel cells, due in large part to Unwerth‘s expertise. By working together with Continental AG as the largest industrial partner in the „HZwo – Antrieb für Sachsen“ Cluster of Innovation, the new Fuel Cell Materials Laboratory on the Chemnitz University of Technology campus is now one of the most modern H2 laboratories in Germany.

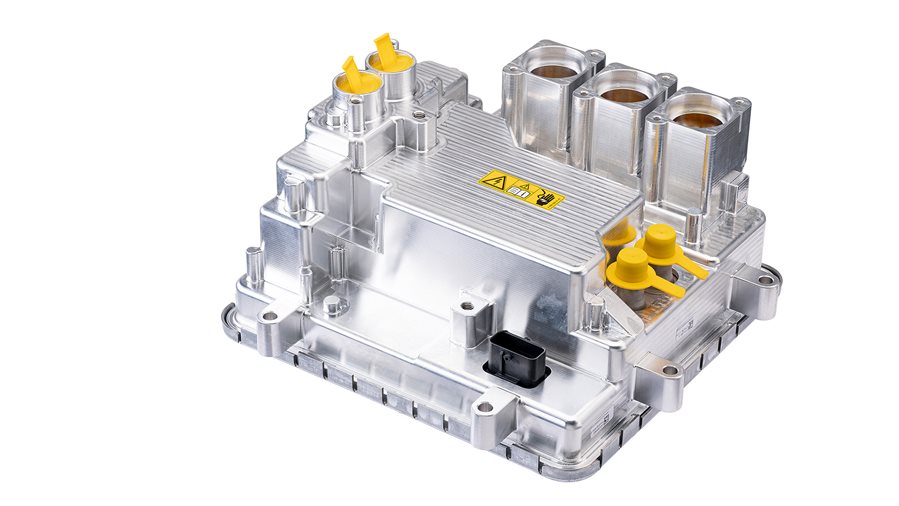

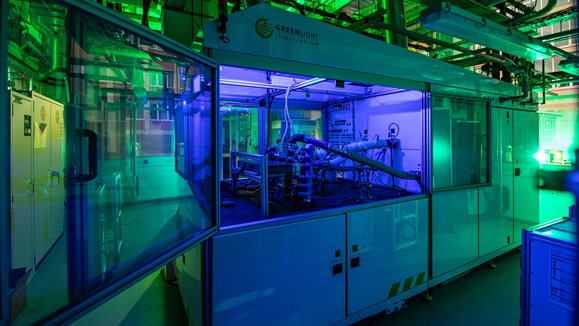

“The special technical equipment at the laboratory is unparalleled in the European university landscape“, says Prof. Dr. Thomas von Unwerth. “The heart of the new system is a high-performance test bench that accommodates permanent testing of powertrain performance up to 150 kilowatts. In the future, the test bench can also be converted up to 300kW. This lays the foundation for the development of next-generation fuel cells and fuel cell systems at Chemnitz University of Technology.“ Geared towards a networking-based outlook, third-party companies can also use the laboratory.

“It is clear that Chemnitz University of Technology takes on critical, future-oriented questions dealing with the economy and society as a whole. Undoubtedly, this includes the question of an economically and ecologically sensible alternative to the internal combustion engine. The fact that Chemnitz University of Technology is a leader in the field of hydrogen fuel cell technology is quite evident, as shown by the commissioning of this test bench, something unparalleled in the university sector throughout Europe“, explains Prof. Dr. Gerd Strohmeier, President of Chemnitz University of Technology.

Electric drivetrains with fuel cells are expected to be an important option, especially for larger vehicles and long-range commercial vehicles. In order to test the performance of the fuel cell under different conditions, the new test bench is able to simulate changing environmental conditions and workloads, something that is essential for assessing the performance of a hydrogen fuel cell. The tests are carried out at different temperatures, pressure conditions and humidities, and additionally under simulation of different load requirements, such as weight or mountainous terrain. Initial measurement tasks having to do with research projects involving innovative materials for fuel cells are already underway, and are creating the basis for mass production of particularly efficient and economical components and elements.

As a representative of state government, State Minister Dulig agrees that it is of primary strategic interest to the region to play an active role in shaping the change towards electrification of mobility, thereby ensuring a continuation of its success. In doing so, he emphasizes the importance of powertrain technology, particularly in Saxony, in order to ensure competitive, innovative employment in the medium-sized business sector.

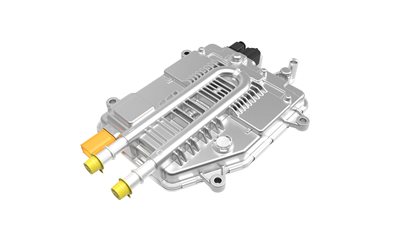

Powertrain fuel cells are still struggling to deal with high costs. Therefore, one of the first two Continental projects in the fuel cell laboratory is dedicated to the development of new so-called “bipolar plates“. These metallic plates are a central component of the fuel cell stack. They disperse gases and dissipate the current generated by their reaction. “The goal of the project is the preparation of a large-scale production of new bipolar plates with a higher energy density, which allows for smaller dimensions and overall makes more economical systems a possibility“, explains Rebhan. In addition, controllers and control algorithms for the efficient operation of fuel cells will be developed during the course of a second project.

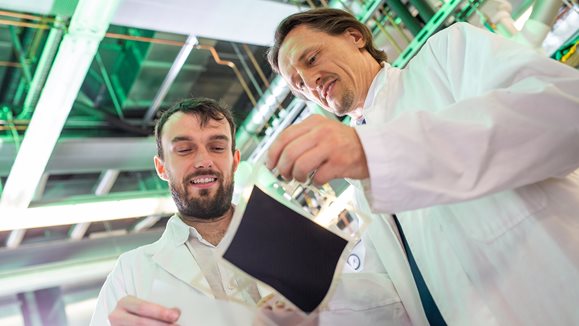

Thomas von Unwerth sees the cooperation as a win-win for both sides: “Continental, as the largest industrial partner in the “HZwo” Cluster of Innovation network, brings extensive knowledge of vehicle utilization, control technology and components for fuel cells. Combined with our expertise, this makes for an ideal foundation for the development of efficient fuel cell solutions and the development of further economic industrialization.“

The technical equipment of the high-performance test bench is unique in the university landscape throughout Europe. A special feature is the permanent testing of drive powers of up to 150 kilowatts. In the future, there will also be the option of converting the test bench to 300 kW.

© TU Chemnitz / Foto: Jacob Müller

© TU Chemnitz / Foto: Jacob Müller

© TU Chemnitz / Foto: Jacob Müller

© TU Chemnitz / Foto: Jacob Müller

© TU Chemnitz / Foto: Jacob Müller

_1920x1080px.jpg?width=579&resizemode=force)

New high-performance test station for fuel cell research inaugurated at Chemnitz Technical University. In the picture from left: Prof. Dr. Gerd Strohmeier, Rector of Chemnitz Technical University, Stephan Rebhan, Head of Powertrain Technology & Innovation (Continental), Martin Dulig, Minister of Sta

© TU Chemnitz / Foto: Jacob Müller

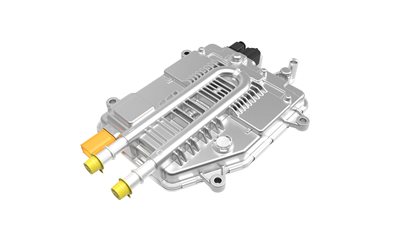

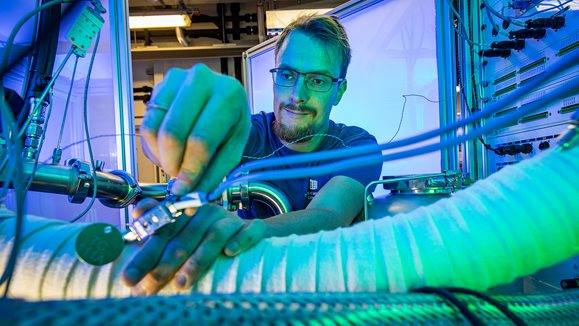

The heart of the new fuel cell laboratory is a high-performance test bench for the permanent testing of drive powers of up to 150 kilowatts.

© TU Chemnitz / Foto: Jacob Müller

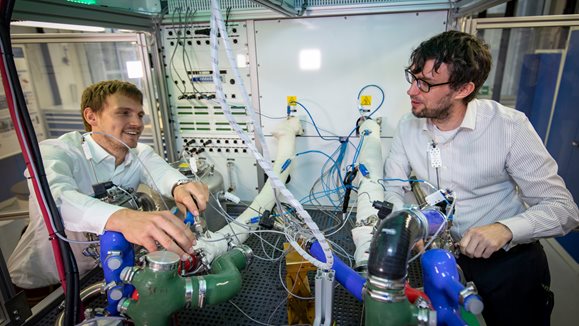

In his fuel cell laboratory Prof. Dr. Thomas von Unwerth (pictured right) and laboratory manager Vladimir Buday combine electrical and chemical engineering with mechanical and industrial engineering.

© TU Chemnitz / Foto: Ronald Bartel