.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

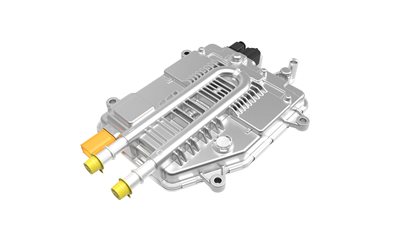

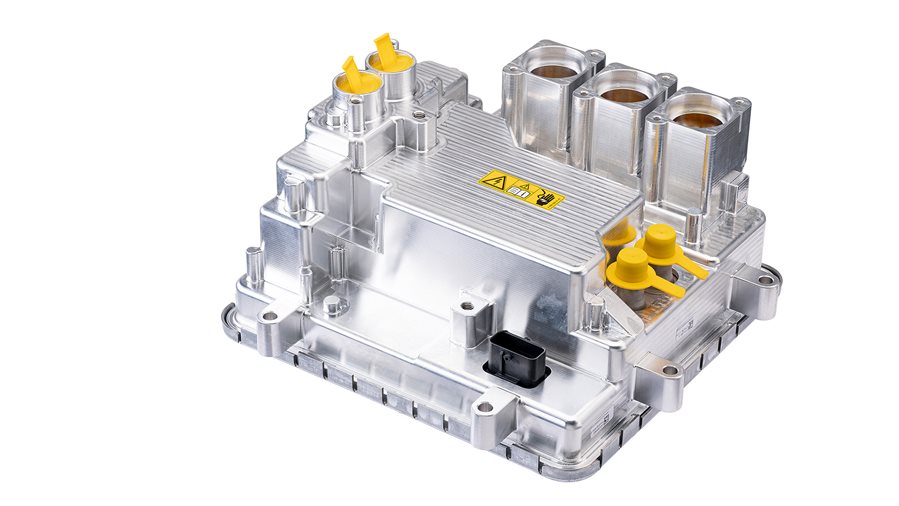

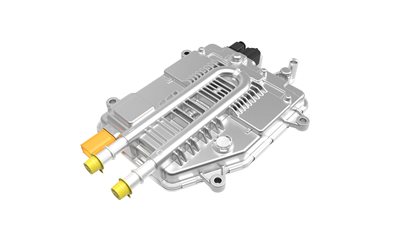

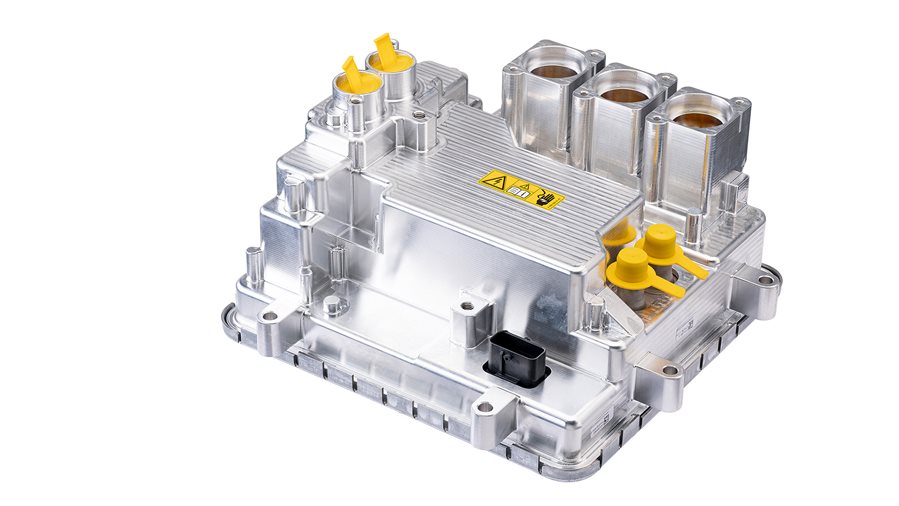

Regensburg (Germany), Bad Nauheim (Germany), April 25, 2024. Vitesco Technologies, a leading international supplier of modern drive technologies and electrification solutions, and Sanden International (Europe), a leading global supplier of automotive thermal management technology, have joined forces to develop an Integrated Thermal Management System for Battery Electric Vehicles (BEVs). Within the future-oriented pre-development project, Sanden develops the compact refrigerant unit with the natural refrigerant propane (R290), while Vitesco Technologies develops the heat energy distribution system realized by a coolant distribution unit with water/glycol. The building blocks of the coolant unit are the coolant pumps and Coolant Flow Control Valves (CFCV) plus sensors. Depending on the application, the coolant valve can have between 5 and 13 ports to connect heat sinks and heat sources.

By integrating the entire thermal management functions and features into one indirect system, several advantages such as flexible adaptation, reduced complexity, reduced effort in the vehicle manufacturing process, system cost reduction for the OEM, and conformity to regulations, including the upcoming per- and polyfluoroalkyl substances (PFAS) ban in Europe, can be achieved. Furthermore, the new technology will increase driving range in cold conditions, enable fast charging, and provide thermal comfort inside the cabin.

For the vehicle manufacturers the Integrated Thermal Management System will offer simplified assembly because a lot of the current complexity of heating and cooling will be integrated in the pre-assembled module.

“Holistic thermal management is the more sustainable approach. That is why we prepare ‘green’ technology for a system solution together with Sanden that will be ready for the natural refrigerant propane,” Rösel adds.

The new Integrated Thermal Management concept is presented to a technical audience for the first time at the 45th International Vienna Motor Symposium.

© Vitesco Technologies GmbH (exclusive rights)