.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

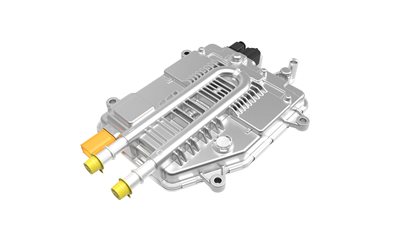

Limbach-Oberfrohna, May 21, 2024. KYBURZ Switzerland AG, a pioneer in electromobility, and Vitesco Technologies, a leading international supplier of modern drive technologies and electrification solutions, have concluded a cooperation agreement for the Limbach-Oberfrohna site in order to jointly industrialize a recycling process for lithium-ion batteries developed by KYBURZ.

KYBURZ and Vitesco Technologies are thus joining forces and their expertise to bring the next generation of recycling systems for LFP batteries to market maturity. KYBURZ contributes its expertise and practical experience in battery recycling, while Vitesco Technologies has extensive expertise in (process) automation and production technology.

Lively exchange at the first joint workshop: KYBURZ is a pioneer of direct battery recycling, Vitesco Technologies contributes decades of experience in industrialization.

© KYBURZ

The increased use of low-cost battery chemistries such as lithium iron phosphate or the up-and-coming sodium ion technology poses new challenges for the established recycling industry. Only lower process costs will make it possible to recycle such inexpensive batteries at a cost-covering rate. The direct recycling process developed by KYBURZ allows for precisely that. Since 2020, KYBURZ is operating a first plant (LIBERTY) in productive use at its headquarters in Freienstein, Switzerland.

The direct recycling process developed by KYBURZ makes it possible to recycle inexpensive batteries at a cost-covering rate. Since 2020, the first "Liberty" plant has been in productive use as a pilot line at the company's headquarters in Freienstein, Switzerland.

© KYBURZ

It is the declared aim of the cooperation agreement to make battery recycling economical, efficient and sustainable. “At the same time, it offers attractive future prospects for the Limbach-Oberfrohna site, where series production of diesel injectors will be phased out by 2028,” explains Plant and Site Manager Dr. Carsten Czenkusch. “With sustainable battery recycling, we are bringing a promising future technology to the site – naturally also with the aim of securing jobs in the long term.”