.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

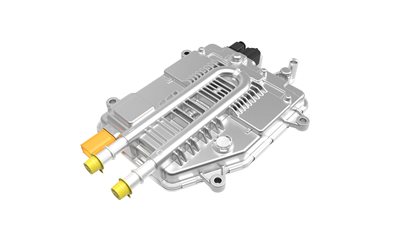

Regensburg (Germany), May 22, 2024. Vitesco Technologies, a leading international supplier of modern drive technologies and electrification solutions, will deliver its EMR3 (Electronics Motor Reducer, 3rd Generation) integrated axle drive to Honda for its all-new CR-V e:FCEV that will be marketed in the U.S. and in Japan later in the year. It is the first time that a Vitesco Technologies’ drive system is integrated into a hydrogen fuel cell electric vehicle (FCEV). Along with the axle drive, Honda will install Vitesco Technologies’ fuel cell stack bypass valve to control the air flow to and from the fuel cell. This bypass valve is based on decades of experience with combustion engine air flow management which now proves to be instrumental for state-of-the-art fuel cell systems.

While the production numbers of the CR-V e:FCEV will probably not match those of other CR-V models, the vehicle is highly innovative: It combines a long range and quick re-fueling of an electric vehicle with a fuel cell system with the option to drive up to 60 kilometers purely electric with power from the 17,7 kWh high-voltage battery. In addition, the driver has a 110 V electric outlet in the car to supply electric devices with up to 1,500 W consumption. Thus, the vehicle can become a clean power source during power outages as well as for outdoor recreational activities.

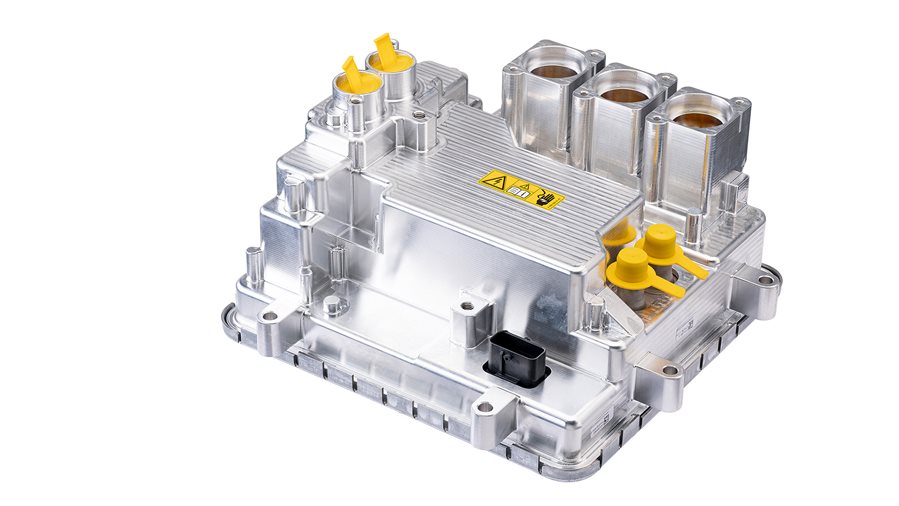

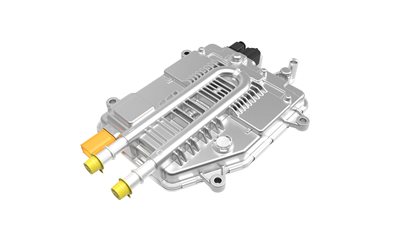

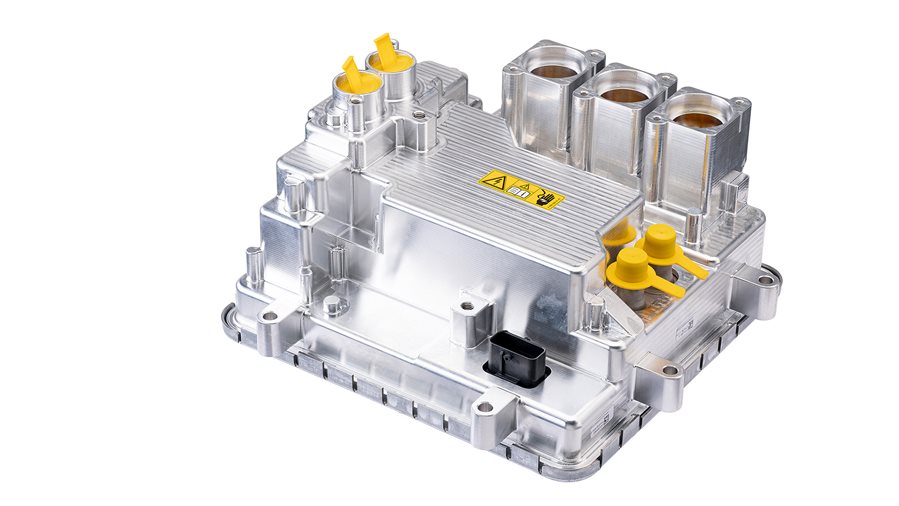

EMR3 axle drive brings proven mature technology, energy efficiency, and attractive driving dynamics

© Vitesco Technologies GmbH (exclusive rights)

Vitesco Technologies’ EMR3 axle drive is a platform that integrates up to three drive system components in one unit: Electric motor, power electronics and reducer. For the Honda e:FCEV Vitesco Technologies will deliver an electric motor and power electronics version without reducer. Owed to very compact dimensions, low weight, high efficiency, and ease of vehicle integration, the EMR3 is one of the most successful Tier1 axle drive systems on the market. By the end of March 2024 more than 900,000 EMR3 Vitesco Technologies units were delivered to many brands and models worldwide.

NVH (Noise Vibration Harshness) test bench in Berlin

© Vitesco Technologies GmbH (exclusive rights)

The EMR3 version for the CR-V e:FCEV was jointly developed by experts in Europe, China and Japan. In the Honda SUV it pushes out 174 horsepower and offers 229 lb.-ft. peak torque. With a full hydrogen tank the vehicle is expected to have a range of over 600 kilometers plus an additional purely electric range of more than 60 kilometers. Manufacturing of the EMR3 has commenced at the Vitesco Technologies site in Tianjin, China.