.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

Regensburg, June 21, 2022. With the aim of optimizing the ecological footprint of its products and, in the long term, designing them to be CO2-neutral throughout their entire life cycle, Vitesco Technologies, a leading supplier of advanced drive technologies and electrification solutions, is intensively looking into the so-called Life Cycle Engineering (LCE).

Life cycle engineering (LCE) means that when designing and developing a product, the ecological footprint of the entire value chain is taken into account – from the extraction of raw materials for supplied parts, through their production and transport, to the use of the finished product and its recycling at the end of its life – in order to optimize these aspects using scientific methods.

This will enable the company to analyze and make transparent how its products affect the climate over their entire life cycle.

Vitesco Technologies also contributes its expertise to the “Umwelt Produkt” working group of the Verband der Deutschen Automobilindustrie (association of the German automotive industry), and to several initiatives of the CLEPA regarding life cycle assessments. The company’s expertise is in high demand from automotive manufacturers and suppliers who also want to introduce life cycle assessments in their companies. “Only when you know the CO2 footprint of your own actions or a product, you can also implement suitable measures or select materials to reduce its environmental impact. We can take advantage from years of experience, extensive databases and highly specialized tools,” explains Khosrau Heidary, head of Life Cycle Engineering at Vitesco Technologies.

Prof. Dr. Alexander Martin from the University of Erlangen-Nuremberg and the Fraunhofer IIS, a proven expert in life cycle engineering, considers the company a pioneer when it comes to automating life cycle assessments: “Vitesco Technologies has developed very innovative, scientifically sound concepts in many areas that are unparalleled in the industry. Almost all major companies are working on this topic and are currently in the analysis phase. Vitesco Technologies has already completed that phase and is taking a pioneering role in the supplier industry by implementing life cycle engineering in its corporate processes.”

As long as a product consists of several components, countless possibilities arise for its development and assembly. These include different design methods, materials, suppliers, supply routes and manufacturing methods, as Heidary explains: “We use mathematical methods to determine which combination can optimize the environmental footprint of a product. On this basis, we in the Life Cycle Engineering team, develop an environmentally optimized product – with consistently high quality and the lowest possible costs.”

© Vitesco Technologies GmbH (exclusive rights)

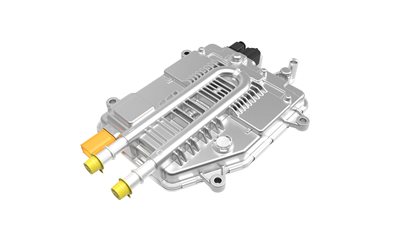

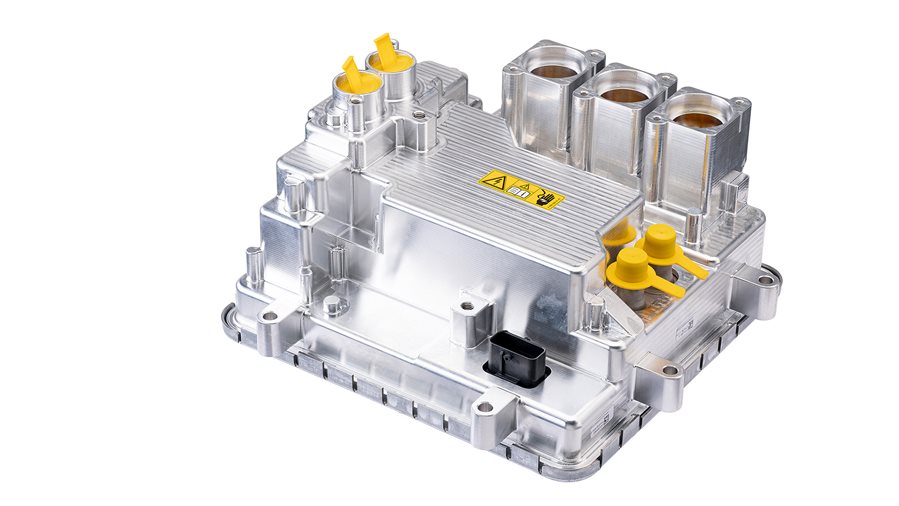

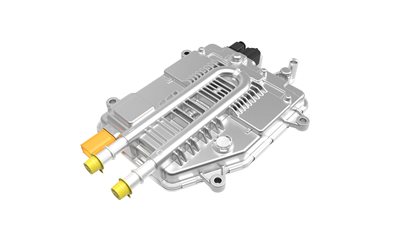

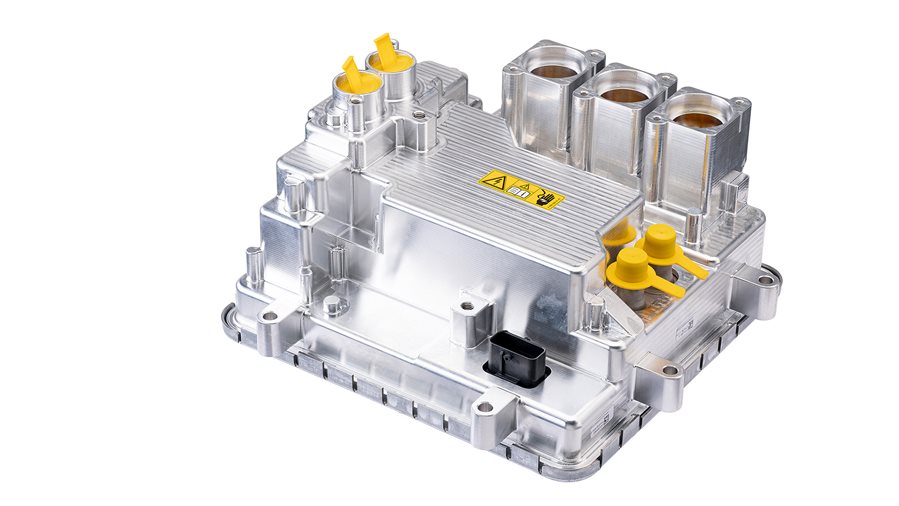

The pilot project for this initiative at Vitesco Technologies was the life cycle assessment of a high-voltage inverter – a particularly complex product with many components that are also used in other areas of electric vehicles. For this alone, around 400 individual components and all steps in the value chain were collected and analyzed. The method, with which life cycle assessments can be mathematically optimized in an automated manner, was developed in cooperation with the University of Erlangen-Nuremberg. Following the successful pilot phase, this method is now being introduced in development, production, and business processes as part of the life cycle engineering program.